High-grade food waste processing

The agro-food industry produces 55% of the total amount of industrial waste in the Netherlands. At present, 80% to 90% is digested to make biogas, composted or processed into livestock feed. The rest is ploughed into the ground or incinerated. Yet a proportion of this waste is suitable for much higher-grade recycling. The Board supports parties in developing their business case and business model for higher-grade food waste processing.

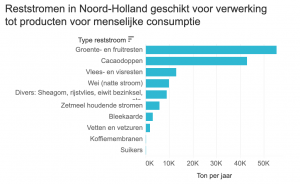

In the province of Noord-Holland, an estimated 1.1 million metric tons of agro-food waste is produced per year. The 10 waste streams that offer the best possibilities for much higher-grade processing are shown in the figure below. In a study conducted by the Province of Noord-Holland and Delft University of Technology, 42 of the 66 major food producers in the province provided access to information on their waste streams, and estimates were made for the rest. The total amount of food waste produced was 142,000 metric tons a year. At 55,500 tons, fruit and vegetable matter proved to be the largest waste stream from these companies, followed by the 43,000 tons of cocoa shells. Annually, 13,000 tons of meat and fish waste is produced, 10,000 tons of dairy waste, 6,000 tons of starch-containing products, 3,000 tons of fuller’s earth, 2,000 tons of fats and fatty acids, and 200 tons of sugar and coffee waste. In a pilot project, the flavourings company Exter and the Amsterdam Green Campus have started work on the two largest waste streams: fruit and vegetable waste, and cocoa shells. Combined, these two streams amount to nearly 100,000 tons of waste.

After processing, the waste streams can certainly still be valuable for human consumption, so it is a shame to process them into animal feed or to digest them to produce biogas. However, the volumes of individual products are too small to make the processing economically viable. A partnership has therefore been launched among food waste producers and processers: with larger quantities, processing becomes viable and higher-grade utilisation is possible.

Source: Wageningen University and Research, via reference: J.H. Welink (Delft University of Technology), 2015: Meer waarde uit de reststromen (‘More value from the waste streams’)

From waste to ingredients for soups and desserts

Both waste streams can be processed to make entirely natural ingredients for the food industry, which can be used in products such as soups, ready meals, desserts and baked goods. From the fruit and vegetable waste, around 10% of solids can be recovered (because fruit and vegetables consists of 90% water), which is around 5,500 tons. A much higher amount of solids can be recovered from cocoa shells: almost 40,000 tons. Because cocoa shells comprise a much higher proportion of solids than most other organic food waste, they can be almost entirely converted into powder. The solids or powders can be used in foods as natural ingredients, for which there is a high demand in the food industry.

An example of such an ingredient comes from pineapple. When pineapples are canned, the cores are removed to leave a hole in the centre of the pineapple rings, and discarded. However, the cores can be processed to make a natural powder which can be used in desserts. They also yield an enzyme that can be used to tenderise meat, replacing the artificial additives which are currently used.

The ultimate aim is to develop a factory capable of processing the entire 142,000 tons of waste and producing an output of around 40,000 to 50,000 tons of high-grade ingredients for the food industry. The remaining by-product is largely water.

This factory will require an investment of around €25 million and will provide around 25 jobs. Moreover, the factory may also have a positive effect on the regional business climate: a location close to the factory would be attractive to food producers, as they would be able to have their waste processed more easily, with lower transport costs.

The first phase is a test factory processing the two largest waste streams. This will cost approximately €800,000 and will be able to process 30,000 tons of waste to produce around 3,000 tons of high-grade ingredients.

Circular chain, smart collaboration

Apart from Delft University of Technology, Exter and Amsterdam Green Campus, 12 other waste producers are now involved in the partnership, and there is room for another three or four partners. Markets have already been found for the powders, as Exter and Amsterdam Green Campus approached a number of potential customers in the trial phase. They are willing to use the powders on condition that a consistent supply is guaranteed according to certain specifications. And the price must of course be competitive in the existing market for powders.

Cooperative innovation

The idea is that the regional food producers should become part of a cooperative valorisation factory. They will deliver their waste streams on the same terms as they do in the present market: for some waste streams there is a charge for disposal, while others, such as cocoa shells, have a certain value as a fuel, so the waste processing company pays the producer for them. The cooperative will take the waste on the same terms and process it to a higher grade than the present waste processor does. All in all, the balance of charges and payment comes out at precisely zero for this model. All participants in the cooperative share in the profit.

To realise this unique initiative, full support and cooperation is expected from all parties in government, industry and universities.

Business plan: launch at the beginning of 2019

The business plan has been prepared, and half of the necessary finance is in place. Ad van Vugt of Exter hopes to raise the total amount by the end of 2018, and a funding application to the Province of Noord-Holland is currently under consideration. If all goes well, construction work on the test factory can begin at the beginning of 2019. For work on the factory and further study, research centres and academic institutions from vocational to university level are collaborating at the Amsterdam Green Campus.

Future

If the pilot is a success, it will be possible to consider scaling up in the Amsterdam Metropolitan Area to a full-scale factory, and processing waste streams from the Green Ports and Seed Valley, and from the provinces of Zuid-Holland, Flevoland and Utrecht in addition to Noord-Holland. The turnover of the final factory could be €17 million by 2024. The profit margin would be around 27%, which means that the net profit in 2024 could be €5.5 million.

Role of the Board

The Amsterdam Economic Board helped to set these developments in motion by conducting thorough market research and bringing together the parties concerned within the scope of the Board’s material transition programme. This is the collaborative programme in which waste streams are combined and upgraded at the scale of the Amsterdam Metropolitan Area to create new material streams.

Read more

This is part 2 of a series of articles on the Amsterdam Metropolitan Area’s material transition programme.

- Article 1: Half a million data servers a year discarded in the Netherlands

- Article 2: High-grade food waste processing

- Article 3: Roadside grass as a green raw material

- Article 4. Major steps in e-waste: recycling electronic equipment

- Article 5: Pilot launched to recycle millions of nappies

- Article 6: From discarded textile to new thread

- Article 7: Organic waste: the start of something beautiful

Source: Delft University of Technology, via reference: J.H. Welink (Delft University of Technology), 2015: Meer waarde uit de reststromen (‘More value from the waste streams’)

2 July 2018

Read more about

Contact us

Want to keep up to date?

Get the best regional news and events (in Dutch) via the Board Update newsletter

Share this news

Want to keep informed?

Follow us daily on LinkedIn and sign up for the Board Update newsletter.

Read more

- The top 100 AI tools based in the Amsterdam Metropolitan Area are shown ...

- During the Tech and AI kick-off on 26 March at NEMO Science Museum, ...

- Flexible charging, energy sharing, and the use of batteries – that’s what ...