Level playing field voor circulaire werkkleding

Circulaire werkkleding kan een belangrijke bijdrage leveren aan de mooie ambities van de Green Deal Circulair Textiel. Tijdens de eerste Meetup Circulaire werkkleding blijkt dat veel spelers in de keten al met het onderwerp bezig zijn én dat er veel van elkaar te leren valt.

De Metropool Amsterdam heeft grootse textielambities: in 2030 gaat er geen circulair textiel meer de verbrandingsoven in. In de Green Deal Circulair Textiel werken uiteenlopende partijen vanuit verschillende invalshoeken aan dit onderwerp. Zo is er al een Denim Deal gesloten, is de inzet op een Reparatie Shared Services Centrum, de ontwikkeling van circulaire beschermende kleding voor zorg en wordt er gewerkt aan de integratie van circulaire principes in onderwijs en onderzoek.

De Amsterdam Economic Board brengt in deze eerste meetup over circulaire werkkleding, producenten en opdrachtgevers bijeen om dit onderwerp verder uit te diepen. “We hopen zo te zien wat er al gebeurt en tegen welke uitdagingen je aanloopt als je je met circulaire werkkleding bezighoudt”, zo vertelt Claire Teurlings, lead Circulaire Economie van de Board bij de opening.

NTA voor circulair textiel

Marien Groenendijk (voormalig directeur van Groenendijk Bedrijfskleding) zet zich persoonlijk in om werkkleding circulair te krijgen. Zo werkt hij onder meer met verschillende organisaties mee aan de NTA (Netherlands Technical Arrangement) voor circulair textiel van het NEN. De NTA beschrijft wat we kunnen verstaan onder circulair textiel en vormt de norm voor producenten en opdrachtgevers. “Circular design gaat een belangrijke rol spelen in de NTA, zodat we gerichter en hoogwaardiger textiel kunnen gaan verwerken.”

Groenendijk: “Bij Groenendijk worden klanten gemotiveerd om mee te gaan op de circulaire reis, maar veel technische kleding met allerlei veiligheidsnormeringen kan nog niet hoogwaardig opgewerkt of gerecycld worden. Dan wordt aandacht besteedt aan andere zaken.”

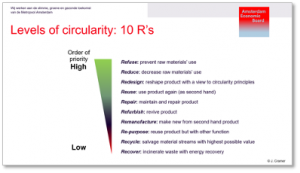

Bijvoorbeeld aan reduce, en refuse, twee R’en die hoog staan op de circulariteitsladder, waarvan je een afbeelding ziet. “De klant van Groenendijk ontvangt bijvoorbeeld niet standaard meer een pakket met broek en een rok voor vrouwen, maar medewerkers kunnen zelf een pakket samenstellen. Bij een andere klant werken ze aan een retoursysteem voor kleding die weinig gedragen is en eventueel refurbished kan worden aangeboden.”

Circulaire werkkleding voor Albert Heijn

In het afgelopen jaar hebben de 100.000 medewerkers in de winkels van Albert Heijn nieuwe circulaire werkkleding gekregen. Bart Hofmans van Ahold Delhaize vertelt hoe zij als opdrachtgever in het aanbestedingsproces veel vrijheid gaven aan de potentiële leveranciers. “We hebben eerst zorgvuldig een kleine groep potentiële leveranciers geselecteerd. Die hebben we onze ambitie geschetst en gevraagd om te komen met een oplossing. Door weinig voorwaarden te stellen konden we optimaal gebruik maken van hun innovatiekracht. In nauwe samenwerking met de medewerkers zijn we tot een selectie gekomen van het beste voorstel. En dat hebben we vervolgens in een aanbesteding aan de markt voorgelegd.”

Die manier van werken bevalt zeer goed, zo vertelt Shirley Schijvens van Schijvens Corporate Fashion, het bedrijf dat de aanbesteding won—hun grootste opdracht ooit. Twee interessante onderdelen zijn het retourlogistieksysteem dat met PostNL werd ontwikkeld. Hiermee wordt afgedankte kleding ingezameld zodat er in Turkije weer nieuw garen van gemaakt kan worden.

Ook de openkostprijscalculatie bleek een schot in de roos voor Albert Heijn. Hiermee kregen ze inzage in de kosten van alle verschillende onderdelen van deze complexe operatie, zodat ze op elk onderdeel een afgewogen en duurzame en circulaire beslissing konden nemen.

Interessante samenwerkingen

Zoals vandaag ook blijkt, gebeurt er al veel rondom circulaire werkkleding. Groenendijk doet mee aan het Europese onderzoeksproject Circtex. Hierin onderzoeken verschillende partijen in de keten nauwgezet hun bijdrage aan recycling en circulaire productie van werkkleding.

En Rick Schurink, commercieel directeur van producent Texet, gaat in op de uitdagingen voor grotere producenten van ‘off the shelf’ producten. Grote stappen zijn eerst gezet op het gebied van verduurzaming van de materialen. Nu bij hen die basis klopt zijn ze circulaire stappen aan het maken in een Vlaamse samenwerking. Hiervoor is een zogenoemde Vereniging Zonder Winstoogmerk opgezet. “Met drie concullega’s en wasserijen denken we daarin na over hoe we bijvoorbeeld de retourlogistiek slimmer kunnen organiseren en hoe meer massa voor circulair textiel te kunnen creëren. In Nederland staan we ook open voor zo’n samenwerking.”

Logistiek, standaardisering en educatie

In de breakoutrooms blijkt ook dat er veel behoefte is aan het uitwisselen van ervaringen en samenwerking op dit vlak. Zo is Shell bezig met een aanbesteding voor uniformen op de tankstations. Er zijn nog veel vragen: bijvoorbeeld over de logistiek rondom inzamelen en hergebruik en wat doe je met uniformen die nog goed zijn van medewerkers die vertrekken? Misschien kunnen ze aankloppen bij de gemeente Amsterdam, die net een aanbesteding heeft gedaan voor de boa-uniformen. Daarin pakken ze onder meer het probleem aan dat sommige boa’s nu soms wel tien truien hebben liggen en wordt geretourneerde gedragen kleding alsnog ingezet.

Yvonne Onnink van Vattenfall zegt dat haar bedrijf tot nu toe vooral maatwerk inkocht, maar dat dat een dure oplossing is. “Misschien moeten we naar meer standaardproducten toe. Ik zou graag eens met andere bedrijven kijken of wij samen massa hiervoor kunnen creëren.”

Sofie Rockland van producent By Rockland benoemt dat educatie ook een belangrijk onderdeel van de weg naar circulaire bedrijfskleding is. “We zijn nog niet zover dat we de loop kunnen sluiten, ook omdat onze klanten nog aan het begin van dit proces staan. Ik merk dat klanten open staan voor de innovaties die er al zijn in de markt en daar probeer ik ze in mee te nemen. Maar er is nog heel veel onbekend bij de klant.”

Kruistocht in spijkerbroek

Iedereen is nog op een kruistocht in spijkerbroek, stelt Roosmarie Ruigrok van de gemeente Amsterdam en Reflow Project aan het einde van de bijeenkomst vast: de ene kant van de keten zoekt naar de juiste aanbestedingsvragen, en worstelt met de beoordeling van het aanbod, de andere kant innoveert en werkt zo aan circulair textiel. Daarin kunnen zoveel keuzes gemaakt worden.

Er ontstaat ook een gesprek over een eenvoudig te lezen keurmerk of symbool zoals de sterren van het beter leven keurmerk en standaard Service Level Agreements (SLA’s) voor transparantie en om greenwashing tegen te gaan. Hier wordt momenteel bij het ministerie van infrastructuur en waterstaat aan gewerkt.

Vervolgstappen

De deelnemers zijn het erover eens dat we samen moeten werken aan massa maken voor circulaire werkkleding. In een volgende meetup, na de zomer, gaan we verder aan de slag met samen aanbesteden, uitspraken doen over keurmerk, SLA’s en labeling en een ‘off the shelf’ standaard product gezamenlijk te ontwikkelen. Denk dan aan een overall, een softshell of een shirt.

De Handreiking inkoop circulair textiel die deze zomer beschikbaar komt, gaat hierbij zeker helpen en ontvang je in je mailbox. Wij zullen hier in een volgende bijeenkomst aandacht aan besteden.

Tijdens de Meetup #3 Circulair Textiel op 9 september staan diverse onderwerpen van de Green Deal Circulair Textiel centraal.

Wil je meedenken over de volgende stappen, stuur dan een mailtje naar Claire Teurlings.

7 juni 2021

Meer weten over

Neem contact op

Blijf jij ook op de hoogte?

8x per jaar nieuws en events uit de regio: schrijf je in voor de Board Update nieuwsbrief

Deel dit artikel

Wil je op de hoogte blijven?

Volg ons dagelijks op LinkedIn en schrijf je in voor de Board Update nieuwsbrief.

Lees ook deze berichten

- Een nieuwe lichting gedreven jongeren is aangetreden bij Young on Board, de ...

- Met de selectie van vier kanshebbers is de regionale voorronde van de ...

- Met meer dan 80 ondernemers, 40 investeerders en diverse dienstverleners bood LSH Capital Match ...